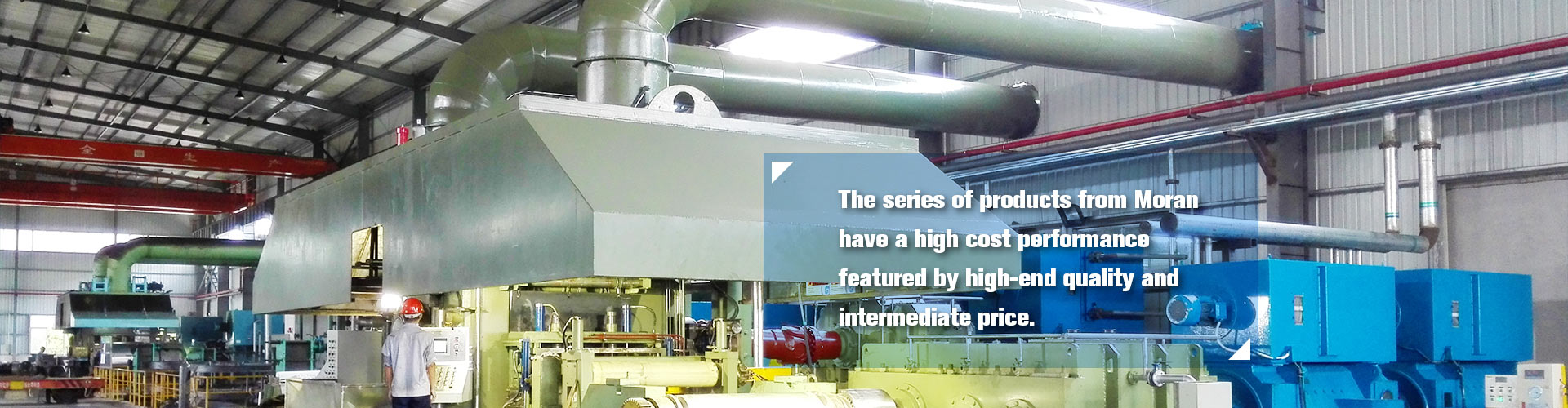

New project of Temper Mill with Tension Leveler for customer of Handan Jintai

In order to provide high quality cold rolling products to customers, Handan Jintai steel Industry decided to have a new Temper Mill with tension leveler to replace the old one. After nearly a month of technical consultation, Jintai steel industry and Moran team reached a procurement agreement. In order to enable customers to use the new equipment as soon as possible, the business director of Moran urged our workshop and R&D center to work overtime for design, manufacture, installation and commissioning. Thank you for your trust and support.

► Customer: Hebei, China

► Services We Offered: Turnkey Solution of Temper Mill with Tension Leveler

► Service Supplier: Moran Machinery

▶ Unit characteristics and process overview

1. Summary

This 1450mm Temper mill with tension leveler is made for the equipment project of cold rolling and skin pass production line. And it includes project, supply and inspection instruction and personnel training of installation, debugging and trying-machine stage along with relevant exterior matching construction and installation project. Our aim is to promote equipment and project, which can guarantee all types and specifications of products, can be produced steadily, according to the requirements of product position of factory party market and present available matching condition. And it has the lowest producing operation cost, the lowest investment for reasonable facilities and the best economical of technology to make users get the best economic benefit.

2. The 1450mm 4-roll Skin Pass Mill Unit has the following design features (design changes can be made according to the process design parameters and requirements determined by the factory's production process):

Profile Control (AFC): The plate type is controlled by the bending roll and work roll to realize the precision requirements of the rolling and leveling control of the thin steel plate.

High precision leveling ability control: The hydraulic pressure and the function of automatic elongation control system (AEC), and the high precision of constant tension control, ensures the high speed continuous rolling. All main drives are equipped with low inertia motor configuration and high precision tension control. All of these provide a guarantee for controlling the flatness and thin gauge of the panel.

High productivity configuration: The skin pass mill is with high rolling speed. It is with maximum coil weight 25 tons, maximum rolling force 6000KN, outlet tension up to 120KN, which can meet the requirements of the leveling process for different specifications of strip steel. The maximum speed of the large capacity full digital speed regulation system with the leveling machine is 240m/min, that can guarantee the demand of large production capacity.

Good maneuver ability and technical economy: The skin pass mill unit is equipped with automatic over belt, fast rolling change, computer control function, all of which is to ensure low labor intensity and efficient production.

High reliability configuration: The whole equipment, transmission and basic automation、AEC system adopts SIEMENS products matched with the strongest solution from domestic manufacturers. The key bearings are all made of high quality carburizing steel, and all key transmission are high precision carburizing gear grinding gears.

3.The tension leveler is a combination of continuous tension straightening machine and roll-type straightening machine, so that the metal strip can be straightened under the combined action of continuous tension and continuous deformation to produce plastic extension and eliminate the defects of the metal sheet, such as edge wave, middle wave, warpage, etc. Bending roller unit has two or more small diameter bending rollers (roll system), its role is to make the strip under tension, after intense repeated bending deformation, to achieve the elongation required by the process, leveling roller unit has one or several leveling rollers (roll system), its role is to level the strip after intense bending. Since the bending and leveling rollers are small in diameter, they are mostly supported by a group of support rollers to form a roll system to improve the stiffness. The steel strip is subjected to strong continuous alternating deformation in the bending deformation zone in the first stage, resulting in plastic extension so that all parts of the strip get uniformly distributed residual deformation, which disappears in the second stage of straightening, so that various three-dimensional plate defects are corrected.

WhatsApp

WhatsApp