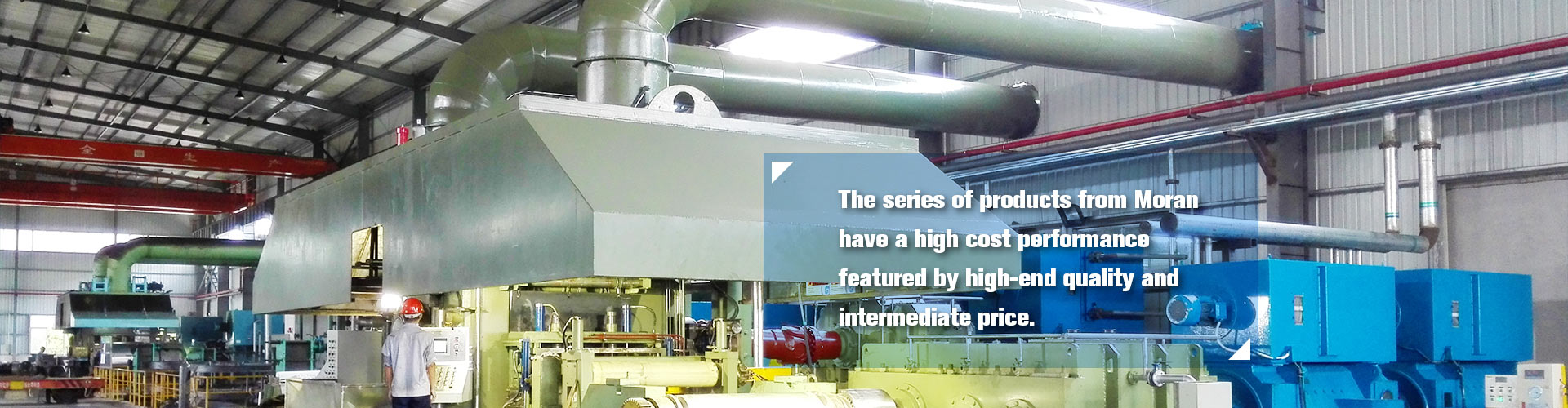

Structure and process characteristics of offset eight high cold rolling mill

Offset eight-high mill is a kind of cold rolling mill with small diameter work roll and unique structure. It is a multi-high mill with side support roll extended to work roll on the basis of four-high mill driven by back-up roll.

From the perspective of the structure of the frame, the partial eight-high rolling mill and the four-high rolling mill are basically the same, but because the rolling mill uses the work roll with small diameter and the roll profile adjustment device, the position of the work roll is relatively stable, and the horizontal stiffness is high, and the overall stiffness is larger than that of the four-high rolling mill, which can roll part of the products of the 20-high rolling mill. Because its structure can be changed into two high, four high, eight high and sixteen high (double eight high) several forms, in order to meet the needs of many varieties, so it is also called multi-purpose rolling mill.

1. Structural characteristics

In this way, the diameter of the work roll is not restricted by torque nor affected by horizontal bending. The diameter of the work roll can be very small, generally only about half of the diameter of the work roll of the same type of four-high mill, only 15%~20% of the diameter of the backup roll, and the rolling force is only half of that of the four-high mill. In this way, the partial eight-high mill can meet the requirements of rolling thin strip and hard to deform metal products just like the multi-high mill. The structure of the partial eight-high mill is simple and similar to the ordinary four-high mill. The complete set of work rolls, intermediate rolls and side backup rolls are installed on the supporting arm rotating around the axis of the side back-up roll, and the side back-up roll is close to the big back-up roll. In this way, the torque of the work roll is supplied without consuming the friction contact with the back-up roll, which has a favorable effect on the work roll. During rolling, the vertical force borne by the large diameter back-up roll is transmitted to the frame through the screw down, and the lateral force borne by the side support phase is also transmitted to the frame through the side beam. The contact between the side back-up roll and the back-up roll is maintained by a spring, and the side back-up roll is mounted on the mandrel by a roller bearing. Equipment investment and maintenance costs are much lower than multi - roll mill.

Like the multi-high mill, the partial eight-high mill has a more rigid roll system structure and roll shape adjusting device, the total bounce value of the mill is small, and the work roll shape can be adjusted at any time during the rolling process, so that the strip steel with small thickness deviation and good shape can be rolled.

The mill backup rolls are driven separately, which allows the use of work rolls with a wide range of roll diameters. Working roll support is simple and fixed, roll change is relatively simple and convenient, and roll loss is small. The friction loss between the rolls is small, and the mill can be lubricated and cooled with emulsion to reduce the friction during rolling.

2. Equipment characteristics

The working stand of partial eight high mill is mainly composed of roll system, press mechanism, neck holding device of work roll, swing door and roll profile adjustment installation.

Compared with the four-high mill equipment, the offset eight-high mill equipment has the following characteristics:

(1) Unique structure of partial eight-high rolling mill

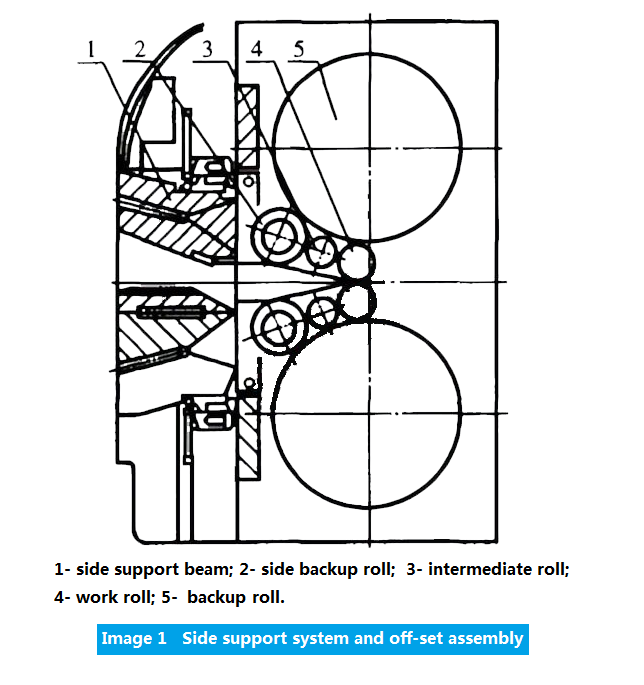

The unique structure of the partial eight-high mill is that the work roll has a side support system and the installation position is off the center line of the back-up roll, as shown in Image 1. During rolling, the work roll is supported by the upper and lower support rolls in the vertical direction and the side support system in the lateral direction. The side support roll and the middle roll are assembled with a fixed bow and then fixed to the side support roll bearing seat. The lateral force acting on the side back-up roll is transmitted to the side support beam through the support of its concentric axis, so that the axis of the work roll, the intermediate roll and the side back-up roll should ensure that the rolling mill roll system has sufficient stiffness. When the side support roll and the support roll work in contact, the intermediate roll can also transfer torque to the work roll, to increase the pressure and reduce the role of sliding between rollers. In addition, the installation of the work roll deviating from the center of the support roll and the neck device of the work roll can ensure the reliable stability of the work roll in reversible and high-speed rolling.

(2) Partial eight-high mill has roll shape adjustment device

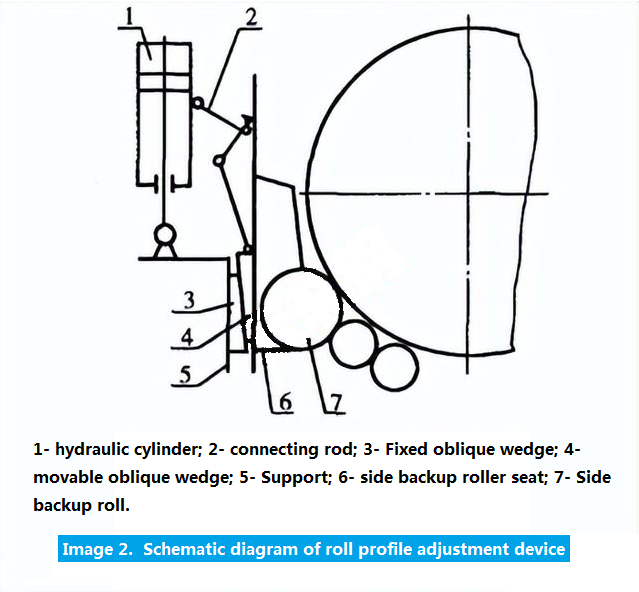

Another feature of the offset eight-high cold rolling mill is the roller shape adjusting device, as shown in Image 2. The roller shape adjusting device is driven by the hydraulic cylinder 1 through the connecting rod 2 to move the four movable oblique wedge 4 up and down. Because of the different slopes of the active cheater, the middle two cheaters have 5 degrees of slope, and the two sides have 3 degrees of slope, and there are still flat blocks on both sides. In this way, different bending deformation can be produced by the side support roll and the middle roll in the oblique wedge movement, thus realizing the plate shape adjustment in the rolling process.

(3) Ratio of length of roll body to diameter of partial eight-high mill

The ratio of roll length to diameter of partial eight-high mill is generally 3~10, and the stiffness of lateral support roll system (especially the middle roll) is low. It is easy to slip and bite between the transmission support roll and the work roll; The axis of work roll, intermediate roll and lateral support roll should be in the same straight line. The stability condition is not easy to master, and the roller diameter needs to be matched, which has higher requirements in manufacturing, installation and adjustment than that of four-high rolling mill.

3. Process characteristics

The production technology of partial eight-high mill is very similar to that of four-high mill, and it has the special point of rolling stainless steel in the specific content. The distribution of each pass pressure is based on the principle of equal pressure rolling, and the relative pressure is reduced pass by pass. Stainless steel deformation resistance is large, work hardening is also large, at the same time the material of different chemical composition and metallographic structure on the pressure has different requirements. Partial eight-spoke mill rolling process has the following characteristics:

(1) Roll shape control

The roll shape control method of partial eight high mill has not only the original convexity of the work roll configuration and the fractional control of the emulsion flow, but also the unique roll shape mechanical adjustment device. As mentioned above, the spoke can also be adjusted by the hydraulic cylinder control of four oblique wedges. That is, four bending forces are generated by the action of the inclined wedge on the length of the roll body to make the work roll flex, and the amount of flexure can be adjusted according to the material and specifications of the rolled strip steel. For example, there is 0.05-0.22mm convexity value of work roll grinding. When rolling strips with a width of 1000mm, with the increase of rolling force, the convexity adjustment of work roll can reach the maximum ± 0.05mm. The adjustment amount is expressed as a percentage on the operating plate, the maximum adjustment amount is 100%, which is equivalent to an increase of 0.10mm in the working roll convexity. Therefore, partial eight high mill has better shape control ability.

(2) Assembly of roll

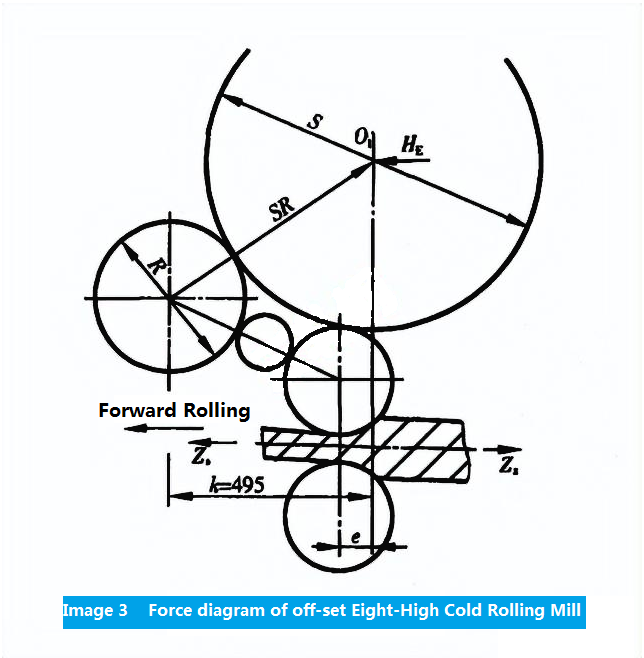

The deviation of work roll from back-up roll is directly related to the stability of work roll rolling. The selection of offset should ensure that the work roll is always close to one side during forward and reverse rolling and under the condition of maximum tension difference between front and back. Therefore, in the assembly of roll, according to the diameter of grinding backup roll, side backup roll and middle roll, the suitable diameter of the work roll and select the appropriate offset. According to the force analysis of roll system of partial eight-high mill (see Image. 3), the work roll offset generates lateral component of rolling force and makes the work roll close to the side support roll. And the support roll friction drive work roll produces tangential force on the work roll. In forward rolling, this force makes the work roll leave the roll seam and lose the stability condition. In this way, the force of the side support roll on the work roll is smaller in forward rolling than in reverse rolling. Therefore, the offset of the work roll should be determined according to the condition that the supporting force of the side support root acting on the working spoke is greater than zero in forward rolling.

4. Conclusion

With the development and progress of modern steel rolling equipment, especially the progress of modern control plate thickness and shape means, the use of eight-high partial rolling mill is limited. Eight-high partial rolling mill must overcome its own shortcomings in controlling plate shape, etc., in order to meet the market demand and be widely used.

WhatsApp

WhatsApp