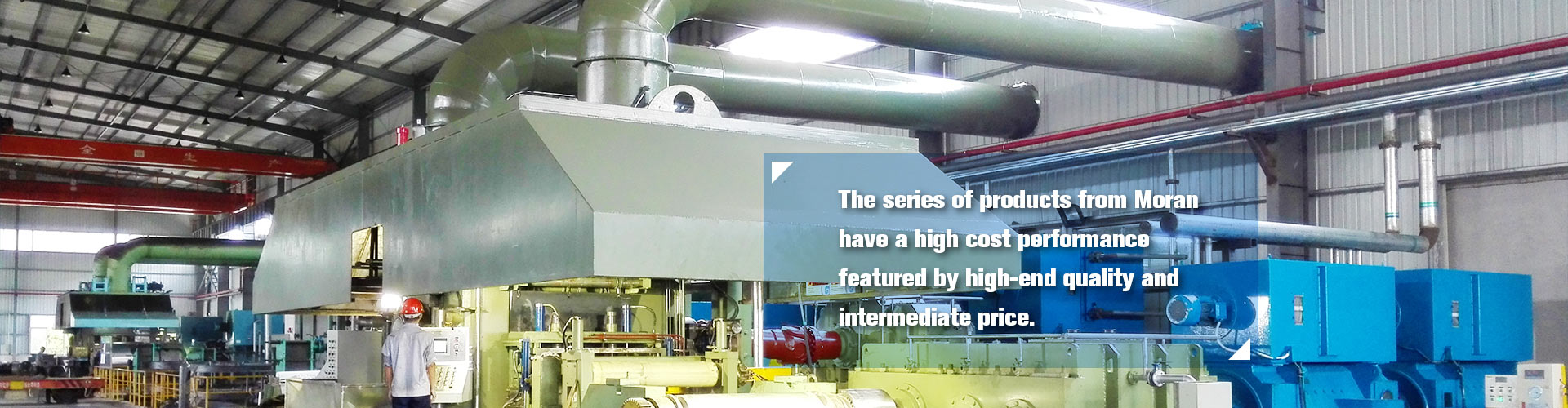

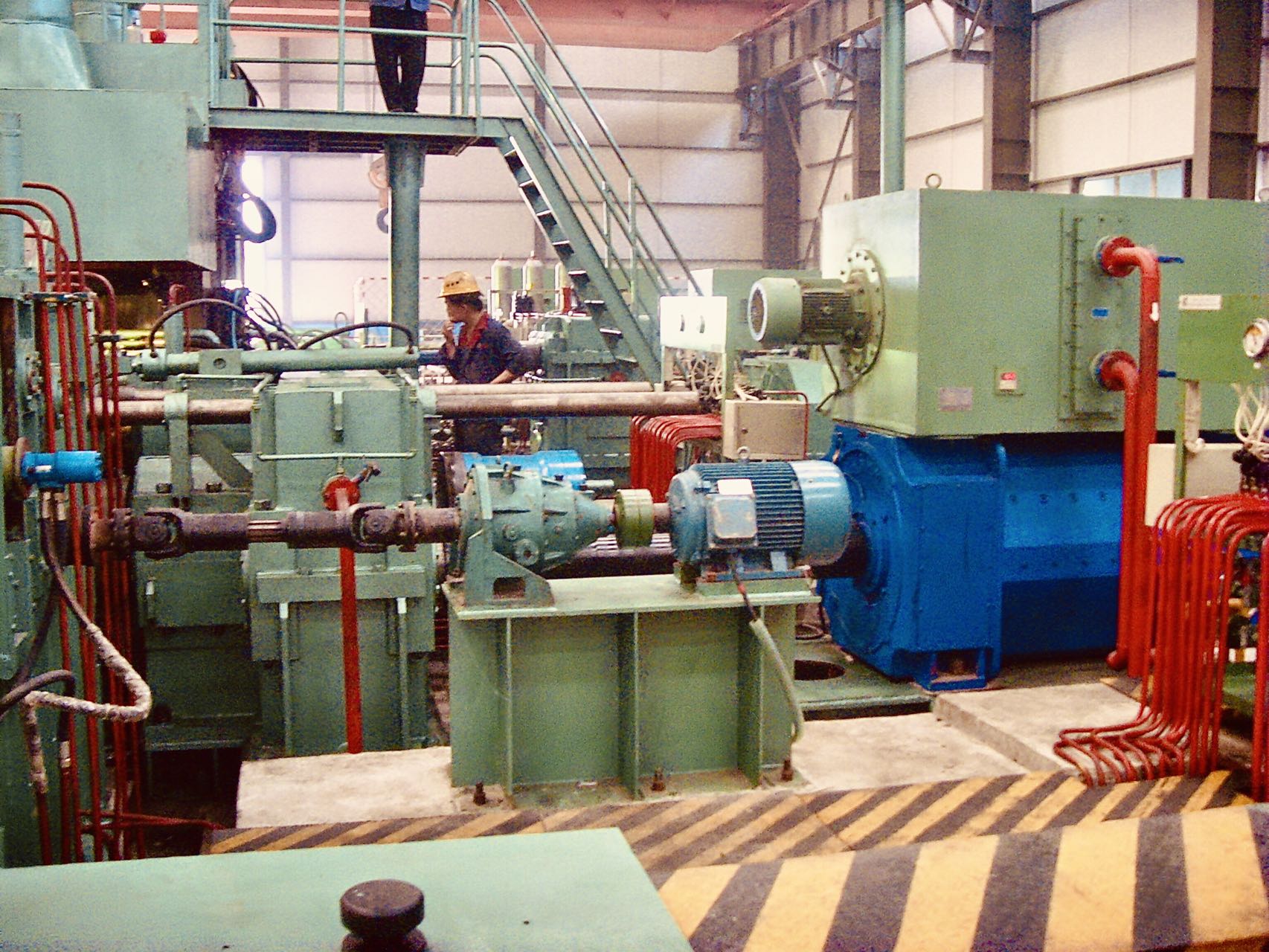

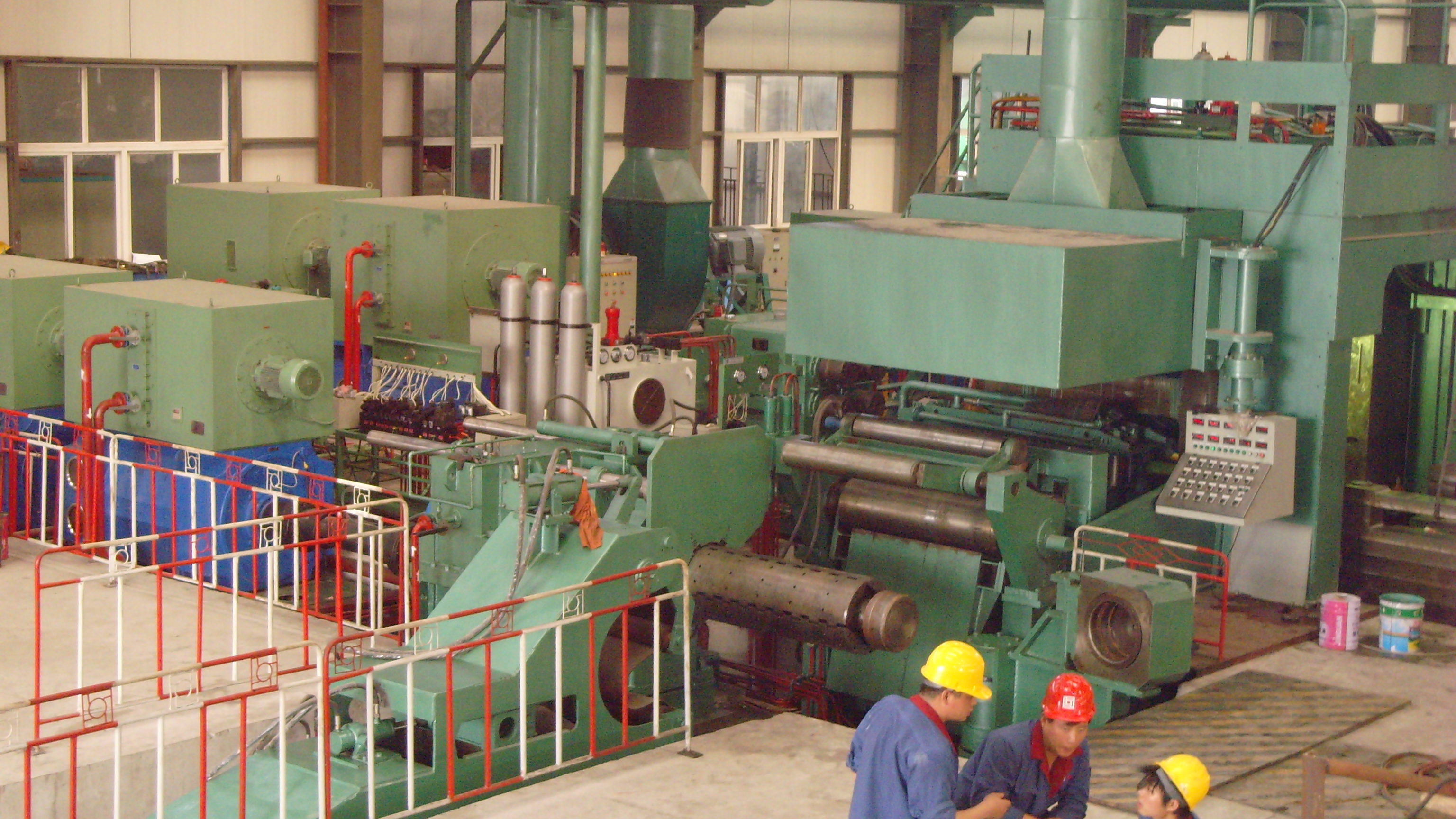

Twenty-roll cold rolling mill

It is applicable to rolling strip difficult for deformation such as stainless steel, silicon steel and alloy steel. It has the maximum tension of 40T, the maximum rolling force of 1000 tons and the highest speed of 600m/min. The stepped roll configuration allows the working rolls to have small diameters and ensures the horizontal rigidity of working rolls. The integrated mill housing design enable the mill to provide sufficient rigidity and spilt design of upper and lower roll boxes ensures large roll gap, allows easy strip feeding and can effectively protect rolls. Meanwhile, the mill is provided with various profile control ways such as setting of backing bearing eccentricity, radian grinding of two intermediate rolls, twitching of one intermediate roll, crown adjustment of A/D supporting roll and injection adjustment of rolling lubricant, thus ensuring good rolling profile. The electric drive system adopts Siemens S7-400 PLC as the main controller and AGC system is controlled by Siemens S7-416+FM458. Key elements, such as MOOG servo valve and SONY magnetic scale, are imported products.

1.Brief Introduction

This 1450mm 20 Hi Reversible Cold Rolling Mill was designed to roll 1.0~3.0mm plain carbon steel, low alloy steel and 200, 300,400 series stainless steel board into 0.2-1.2mm thick as clients’requirement. The model has flexible rolling process, and it can adapt to changing raw materials and product specifications in a wide range, The equipment is relatively simple, taking small space for construction, with low investment, and quick returns.

2.Technical data of the Mill

| No | Specification | Data |

| 1 | Max Rolling Pressure | 9000KN |

| 2 | Max Rolling Torque | 66kN·m |

| 4 | Max Rolling Speed | 500m |

| 5 | Max coiling tension | 400KN |

| 6 | Max threading speed | 30m/min |

| 6 | Max coiling speed | 540m/min |

| 7 | Work Roll Size | Φ63.5mm, material: Cr12Mo1V1 ; Hardness: HRC63-65 |

| 7 | Intermediate roll size | The first Intermediate rollΦ102mm, material Cr12Mo1V1, hardness HRC61-63; The second Intermediate roll: Φ173m, Material: 9Cr2Moor 9Cr2MoV Hardness:HRC59-61. |

| 8 | Driving Roll | Φ173mm, Material: 9Cr2Mo or 9Cr2MoV; Hardness: HRC59-61 |

| 9 | Backing bearing | Φ300mm, Material :bearing steel |

| 10 | The mandrel diameter of coiling machine | φ610~φ596㎜(entire circleφ610㎜) |

3. Product Program

Standard of coming material

| Material quality | Plain carbon steel/low alloy steel/200,300,400 series stainless steel/ silicon steel |

| Mechanical Properties | бs≤1000 N/mm2 ;бb≤1400 N/mm2 |

| Thickness | 1.0~3.0mm |

| Width | 800-1270mm |

| Rolling diameter(interior/exterior) | Φ610mm-Φ2200 |

| The maximum rolling weight | 28t |

Standard of finished products

| Thickness | 0.2-1.2mm |

| Width | 800-1250mm |

| The maximum rolling weight | 28t |

4. Equipment Level

1) Full hydraulic pressure, hydraulic AGC automatic control. It has constant roll gap position control, constant pressure control, roll deviation adjustment, thickness pre control, monitoring function etc.

2) The whole control system adopts the upper computer control management technology, the full digital DC speed control device, the decentralized PLC unit process control and the remote communication networking technology. Through the two stage network, the rolling mill power supply, the AC and DC main motor control, the PLC system, the remote I/0 system, the AGC PLC system, the human-machine interface (HMI) are integrated into one. Unified design of the interface relationship of each system, thus forming the modern automatic control system of the rolling mill.

3) The main operation console is equipped with man-machine interface, which completes the rolling mill status screen display (winding tension value, current value, speed value and other main process parameters) and manual adjustment, rolling process parameter setting, fault alarm and printing report.

4) The main components and hydraulic pumps of the low-pressure hydraulic system adopt domestic high-quality products; the high-pressure AGC hydraulic system and key seals adopt imported products.

5. Sales Performance Table of 6 Hi Cold Rolling Mill

| 序号 | 年份 | 业主名称 | 机组规格 |

| No | Year | Clients | Production Line Specification |

| 1 | 2008 | 广东LS钢铁有限公司Guangdong LS steel Co.,Ltd. | 1450mm 二十辊可逆冷轧机组1450mm 20 Hi reversible cold rolling mill machine |

| 2 | 2006 | BS钢铁制品有限公司 Bd Iron and Steel Products Co., Ltd. | 1450mm 二十辊可逆普碳钢冷轧机1450mm 20 Hi reversible cold rolling mill machine |

| 3 | 2006 | 福建YD不锈钢制品有公司Fujian YD Group Co., Ltd. | 850mm 二十辊可逆不锈钢冷轧机850mm 20 Hi reversible stainless steel cold rolling mill machine |

| 4 | 2006 | 太原LX不锈钢有限公司Taiyuan LX stainless steel Co.,Ltd. | 830mm 二十辊可逆不锈钢冷轧机830mm 20 Hi reversible stainless steel cold rolling mill machine |

6. High end customized Manufacture for Cold Rolling Mill

If the advertised cold rolling mill is not what you need, please fill the

following table, we will offer you what you required.

| NO序号 | Items参数名称 | Specification requirements参数 | Items参数名称 | Specification requirements参数 | Remarks简要说明 |

| 1 | Material Grades原料材质 |

| Purpose of use成品用途 |

|

|

| 2 | Entry thickness 原料厚度 |

| Exit thickness 成品厚度 |

|

|

| 3 | Entry width原料宽度 |

| Inner diameter of finished products成品内径 |

|

|

| 4 | Inner diameter of incoming material原料内径 |

| Outer diameter of finished product成品外径 |

|

|

| 5 | Outer diameter of incoming material原料外径 |

| Annual output年产量 |

|

|

| 6 | Max weight of incoming coil原料重量 |

| Max speed requirements运行速度 |

|

|

7. For more information, please feel free to contact us!

WhatsApp

WhatsApp