Tandem cold rolling mill

This type of mill is a multi-stand continuous rolling mill consisting of four or six high mills. It is a high yield, low cost and high production efficiency machine. This type of unit includes various widths such as 400~1250mm, the fastest rolling speed is 600m/min, the rolling force is up to 1800 tons, the winding tension is up to 20 tons, and there are work roll positive/negative bending rolls, intermediate roll bending rolls, middle Roll twitching, AGC pressing. It can be equipped with double station roll changing machine, roller bearing oil and gas lubrication, reducer thin oil lubrication, and automatic rolling line adjustment device. The electric drive system uses the SIEMENS S7-400 series PLC main controller, the AGC system uses the SIEMENS S7-416+FM458 control, the key components use the imported products, such as the EMG automatic pair, the MOOG servo valve, the SONY magnetic ruler, the POLYTEC laser tachometer, the Dr-Brandt tension meter and so on.

850mm four Hi and six Hi five-stand tandem rolling mill

1. Brief Introduction

The 850mm four Hi and six Hi five-stand tandem rolling mill program is for Mehr Steel Co. Ltd. cold-rolled steel sheet production line project, and includes engineering, supply, and guidance installation and commissioning, supervision and guidance of the commissioning phase and personnel. Training and related external supporting construction and installation project. Our goal is to introduce products that can ensure the stable production of all types and specifications of products in the product outline, the lowest production and operating costs, the lowest reasonable allocation of investment, and the best technical and economical equipment according to the product positioning requirements of the market and the existing supporting conditions. And engineering, so that users get the best economic benefits.

2. Main Technical parameters of cold rolling mill

| No | Specification | Data |

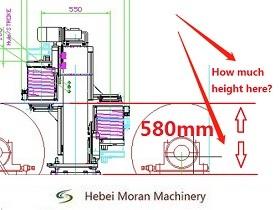

| 1 | Specification of Rolling Mill | Φ230*850/Φ770*820mm four Hi cold rolling mill;Φ210*850/Φ280*820/Φ680*820mm six Hi cold rolling mill

|

2 | Maximum Rolling Force | 7500KN |

| 3 | Coil wearing speed | 0.3-0.5m/s |

| 4 | Max Rolling Speed | 360m/min (the fifth stand is the outlet) |

| 5 | Looper feeding speed | 200m/min |

| 5 | Unwinding tension | Max 25KN |

| 5 | Coiling tension | Max 40KN |

| 6 | Coil reel diameter | Φ508~Φ510mm |

| 7 | Hydraulic Transmission System Pressure | 10 Mpa |

| 9 | Flat bending system pressure | 12 MPa |

| 11 | Main Drive Motor Power: | F1:Z710-2A 1000KW 1 set F2: Z710-2A 1000KW 1 set F3: Z710-2A 1000KW 1 set F4: Z710-2A 1000KW 1 set F5: Z710-2A 1000KW 1 set |

3.Product Program

Standard of coming material

| Thickness | 2.5~4.0mm |

| Width | 500 to 750mm |

| Rolling diameter(interior /exterior) | Φ508/1600/mm |

| The maximum rolling weight | 10t |

Standard of finished products

| Thickness | 0.3-2.0mm |

| Width | 500-750mm |

| Rolling diameter(interior/exterior) | Φ508/(Φ1600)mm |

| The maximum rolling weight | 10t |

4.Equipment Level

The more prominent technical characteristics are as follows:

1) DC drive, full digital DC speed control system (using Siemens 6RA80 control system).

2) Full hydraulic AGC reduction control system. (Pressure hydraulic cylinder, AGC control system, hydraulic station, thickness gauge, etc. have constant roll gap position control and constant pressure control and tilt automatic adjustment control function.)

3) The main motor drives the upper and lower work rolls through a combined reducer and universal joint shaft; the backup roll uses four rows of short cylindrical roller bearings, and the work rolls use four rows of short cylindrical roller bearings. The work roll, intermediate roll and backup roll bearings are lubricated with oil and gas.

4) Through the work roll hydraulic bending roll, the six roll intermediate roll twitch, and the roll cooling, it is ensured that the steel strip with high lateral precision and good plate shape is rolled out.

5) Roll segment cooling control, flow control.

6) Work roll positive bending control.

7) The six-roller intermediate roller is traversed to the setting and positive bending roller control.

8) Zero the rolling line pressure.

9) The main gear unit and the gear and pinion of the coiler are made of hardened tooth surfaces. The thin oil circulating cooling lubricates the tooth surfaces and bearings.

10) The work roll and middle roll change roll change, and the support roll hydraulic cylinder is pushed out and pulled in and replaced.

11) Adopt Siemens DC speed controller to realize basic automatic control, process parameter detection, display and control. Fault detection, display, and alarm of critical parts of equipment.

12) When the host outlet rewinds linkage, it has the function of strip length memory, automatic deceleration at the end of the belt; it has the functions of overload protection, automatic tape break protection and emergency shutdown of the whole machine; it adopts the field bus to constitute the whole network system, the main operation Taiwan set up man-machine interface, dynamic screen display.

13) Cut shears with flying shears.

14) Using two winders, automatically rolling from No. 1 to No. 2 after cutting.

5.Sales Performance Table of 4 Hi Cold Rolling Mill

| 序号 | 年份 | 业主名称 | 机组规格 |

| No | Year | Clients | Production Line Specification |

| 1 | 2017 | 揭阳YS带钢有限公司Jieyang YS Steel Coil Co.,Ltd. | 550mm五连轧机组 550 mm 5 Stand Tandem Cold Rolling Mill |

| 2 | 2013 | 河北HX金属制品有限公司Hebei HX Metal Products Co., Ltd. | 850mm五连轧改造 850mm 5 stand tandem cold rolling mill modification |

| 3 | 2007 | BS钢铁制品有限公司 Bd Iron and Steel Products Co., Ltd. | 850mm五连轧机组 850mm 5 stand tandem cold rolling mill |

6.If the above specification or configuration is not you desired, please fill the following table, we will offer you what you required.

| NO序号 | Items参数名称 | Specification requirements参数 | Items参数名称 | Specification requirements参数 | Remarks简要说明 |

| 1 | Material Grades原料材质 |

| Purpose of use成品用途 |

|

|

| 2 | Entry thickness 原料厚度 |

| Exit thickness 成品厚度 |

|

|

| 3 | Entry width原料宽度 |

| Inner diameter of finished products成品内径 |

|

|

| 4 | Inner diameter of incoming material原料内径 |

| Outer diameter of finished product成品外径 |

|

|

| 5 | Outer diameter of incoming material原料外径 |

| Annual output年产量 |

|

|

| 6 | Max weight of incoming coil原料重量 |

| Max speed requirements运行速度 |

|

|

7. The Range of Our Main Cold Rolling Mills, Cold Rolling Production Line.

| Specification of Cold Rolling Mill |

| roller Type | 4-roller , 6-roller, 8-roller, 12-roller, 20-roller cold rolling mill. |

| Stand Type | single-stand reversible cold rolling mill; tandem cold rolling mill( from 3 stands to 6 stands) |

| Size of finished products | Width: from 350-1450mm; Thickness: from 0.1mm to 3.0mm |

| Application | our range of products covers all areas of the cold rolling industry, suitable for the production and upstream & downstream sectors of cold-rolled products such as plain carbon steel, stainless steel, alloy steel coil and plate. |

Hebei Moran provides the customers with all-around, high value-added pre- sales & after-sales services. Factory design, selection of utility & auxiliary facilities, unit process layout, civil foundation design reference, as well as the well-rounded training combined with theory and hands-on exercises for line operators and maintainers, all are freely available.

Our advantage:

1) Customized Production

2) High cost-effective product

3). All-around pre-sales & after-sales services

4) Independent intellectual property rights

For more information, please feel free to contact us!

WhatsApp

WhatsApp